Professional Investment Casting Service

Selection Hardware offers production services and products made through the precision lost wax investment casting process. We have continued to manufacture more and more accurate and complex casting parts that used in more and more industries, such as automobiles, medical equipment, aviation, ships, internal combustion engines, gas turbines, machine tools and other manufacturing industries. If you have any metal parts want to be customized, either for prototype or mass production, feel free to contact us now!

What is Investment Casting Process

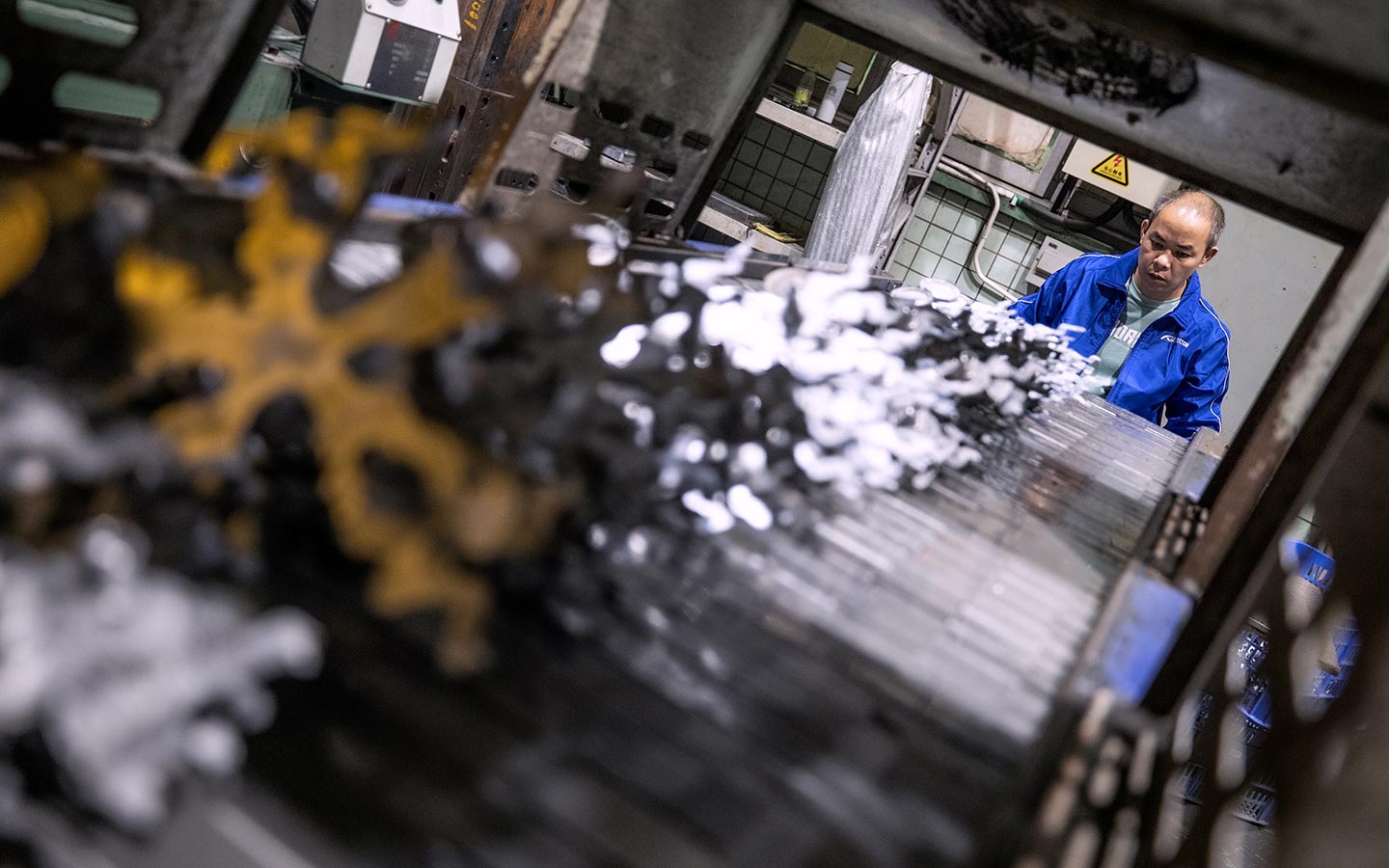

Investment Casting workshop process is also known as Precision Casting and Lost Wax Casting. Its working principle is to make a wax mould, and then coat the refractory ceramic material on the wax model. Once the ceramic material hardens, its internal geometry takes on the shape of the casting. Then the wax is melted, and the molten metal is poured into the cavity where the wax pattern is located. After waiting for the metal to solidify, the shell is then broken to obtain the casting part.

Advantages of Lost Wax Investment Casting process

- The dimensions of the investment casting parts are highly accurate

- The surface finish of the investment casting parts is very high

- There is no flash or molding line on the investment casting parts

- Almost all kinds of metals suit the investment casting process

- Able to produce parts with very complex shapes and structures

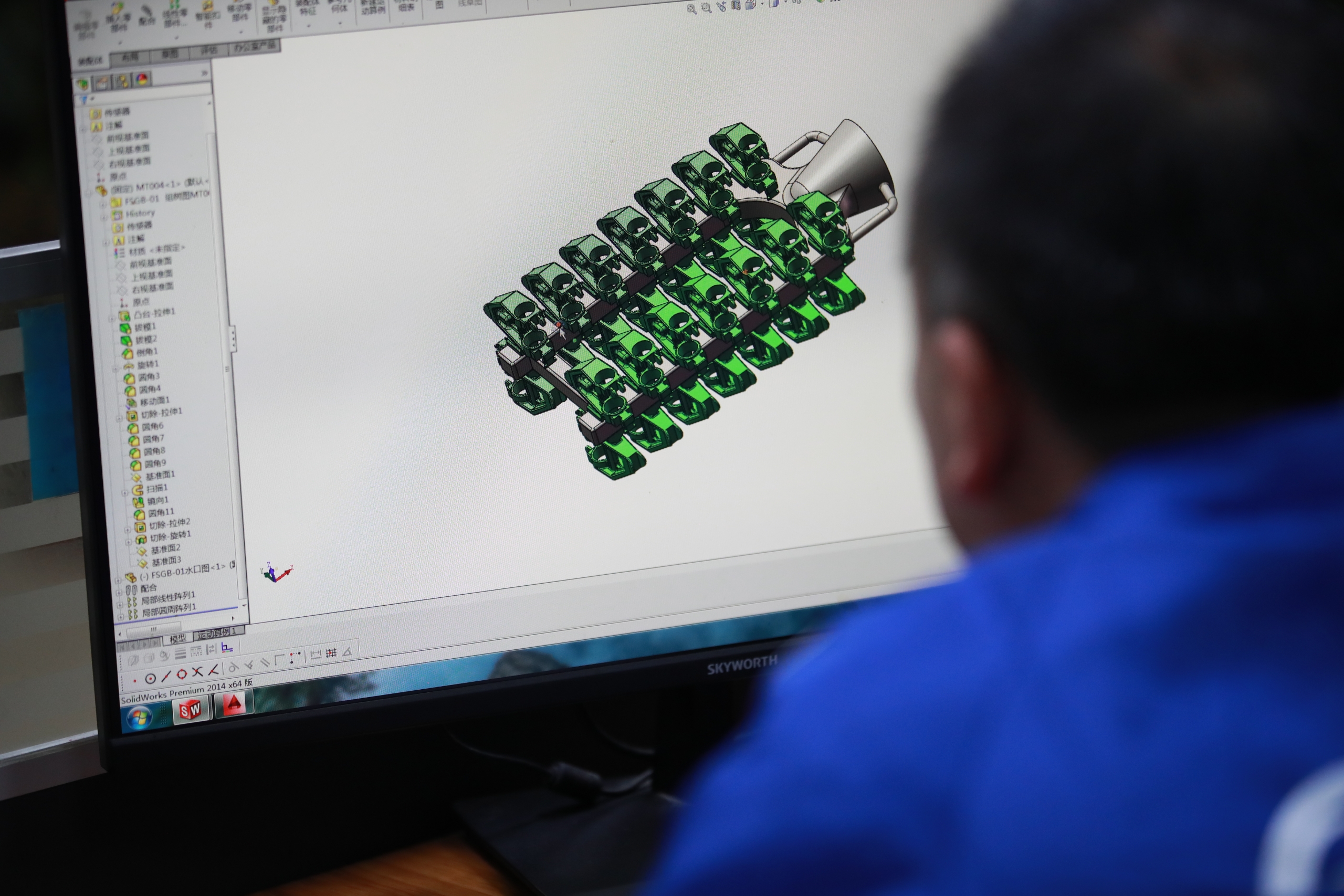

Selection Hardware, Your Right Choice for Investment Casting Supplier

We have an experienced and professional team of production engineers and design engineers who can provide customers with the most optimized casting solutions, including but not limited to choosing the appropriate casting process and materials, which is expected to save 10% cost for customers’ projects. In addition to investment casting, we also can provide sand casting, gravity casting, and die casting processing services, which can meet all customers’ specific requirements. Also, we provide one-stop service from prototyping to mass production.