Presently, CNC machining is a popular manufacturing process with a wide range of industrial applications. However, what do you know about CNC history? Have you ever thought about the history of CNC machines? In this article, we’ll delve into the origination and evolution of CNC machining.

What Is CNC Machining?

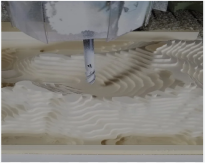

CNC machining is a manufacturing process in which a computer directs machines using programming codes to make a product. CNC machining is a subtractive manufacturing process. This means that the computer program directs these tools (for example, drills, mills, and lathes) to constantly chip away at a workpiece. This continues until the desired product is formed.

Advantages of Using CNC Machining

CNC machining has extensive industrial applications. For example, industries such as aerospace, health, and consumer electronics rely on their advantages. Below are the advantages of CNC machining.

1. CNC Machining Is A High Precision Process

Many industries need tools made from high precision manufacturing processes. A top industry, much known for this requirement, is the Aviation industry. Because they deal with human lives, it is unwise that their machines come from low-quality and low-precision manufacturing process. Therefore, they bank on the high precision capability of CNC Machining.

2.CNC Machining Produces Parts with Accuracy

Another CNC machining advantage is its accuracy. Its programming codes and operator control allows it to produce parts as accurately depicted in the CAD file. Therefore, you don’t need to worry if there are many parts to fit into a bigger component. They will seamlessly fit into each other.

3.Material Choice

When compared with other manufacturing processes such as 3D printing, CNC machining has a valuable edge. That is it supports of many materials. For 3D printing and others, there is a limitation on the type of materials you can choose for your parts.

The only rule about choosing a material for CNC machining is its compatibility with the manufacturing process. Therefore, you will need to consider factors such as: Heat tolerance, Stress resistance, Hardness, Fastening, Design tolerance. Selection Hardware factory can process a variety of materials, such as aluminum, aluminum alloy, zinc alloy, copper, brass, bronze, iron, stainless steel, steel, etc.

CNC History

When you look at the history of CNC machines, you will know that CNC machining did not start as many people think it did. Presently, wherever we say or see CNC machining, we expect a computerized process. However, CNC machining, to be precise, was just recently computerized.

The First CNC Machine

The first CNC machine was credited to James Parsons in 1949. Parsons was a computer pioneer who worked on an Air Force Research Project. The research was about how to produce helicopter blades and better aircraft skin. Parsons was able to calculate helicopter airfoil coordinates with an IBM 602A multiplier. He then fed the data into a punched card, which he used on a swiss jig borer. This information led to the manufacture of many helicopter blades and aircraft skins. According to the accepted CNC history, this was considered the first CNC machine. Parson would later receive the Joseph Maria Jacquard Memorial Awards for his work.

Development of CNC Technology

Before the development of the first CNC machine, some machines could be instructed to make other tools. This was called Numerical Control (NC). You should notice the absence of Computerized (C).

Parsons would later develop the first CNC machine. With this development, there came an evolution. Below is a timeline of the evolution that occurred in the history of CNC machining.

1952 – 1958

As the Cold War became intense, there was a need to improve efficiency and productivity in making many machines and weapons. Therefore, in 1952, Richard Kegg, together with MIT, made the first CNC milling machine known as Cincinnati Milacron Hydrotel. Richard Kegg would later file for a patent for the Motor Controlled Apparatus for Positioning Machine tool in 1958.

1967 – 1972

CNC machining was becoming more recognized across the world. This was due to the Computer-Aided Design (CAD) and Computer-Aided Machining (CAM) development in 1972. CAD and CAM inclusion in CNC machining led to massive developments in CNC machining. However, the two were not regarded as a standard part of the manufacturing process.

1976 -1989

In 1976, 3D Computer-Aided Design and Computer-Aided Machining were included into CNC machining. In 1989, CAD and CAM software-controlled machines became the industrial standard for CNC machines.

Today’s CNC Industry

The evolution of CNC machines is unique. Starting from a simple machine controlled with a punch card to a software-powered machine is enigmatic. Because of the evolution, CNC machining became faster, more precise, and accurate than NC and the first CNC machine.

CNC Machining Applications

CNC machining has developed over time into something of wide recognition worldwide. Because of its advantages, many companies incorporated it into their manufacturing process. CNC machining is not only applicable to the industrial sector only. It is as important at the manufacturing level, which determines its use industrially. Below are the top industries applications and manufacturing capabilities of CNC machining.

1.Industrial Applications

- Automotive

The Automotive industry is a major user of CNC machining. They depend on the manufacturing process in making their prototypes and in production.

- Consumers Electronics

While it might be surprising, the consumer electronics industry also uses CNC machining. Companies such as Apple use CNC machining in their production.

- Aerospace/Military

The two industrial sectors are major users of CNC machining. This is because of its high precision and accuracy. CNC machining is also ideal because it can produce on-demand replacement and upgraded versions of any parts.

2.Manufacturing Applications

- Prototyping

CNC machining is a good process for making prototypes because it is autonomous. Once you have a CAD file, you can send it to a CNC machine, and fabrication will be done in a short time. These properties make it ideal for making prototypes.

- Production

CNC machining has high precision and accuracy, which makes it ideal for making high-quality components. Its wide material supports also improves its use in parts fabrications.

Consequently, companies that use it to make prototypes also use it to create usable final parts.

- Tooling

CNC machining is a gem in the direct manufacturing process and has been of immense help. However, it can also be used in the indirect manufacturing process to help in many processes, such as injection molding.

Conclusion

The history of CNC machining is unique. It has developed more from the first CNC machine that required punch card to a software-based machine that requires little guidance. CNC machining is the top manufacturing process incorporated into many industries.

Make Selection Hardware Your First Choice for CNC Machining

CNC machining is an important part of major manufacturing processes. This is evident in its adoption by many industries and the companies that offer the service to people. When you choose us, you can get to enjoy many benefits including instant online quotation, Design for Manufacturing analysis, strong engineering support, etc.