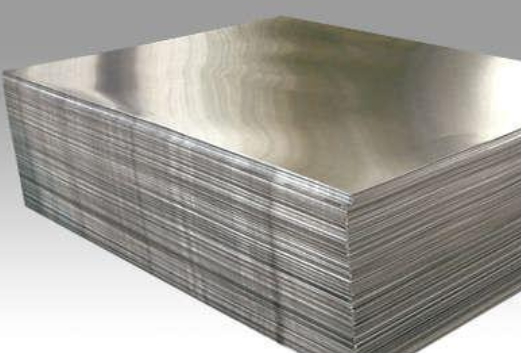

Aluminum alloys remain top-of-the-line materials used in several different industries today. These metals have high relative strength, excellent strength-to-weight ratio, and improved machinability. Among the most popular aluminum alloys for manufacturing are 6061 aluminum and 7075 aluminum. While similar in some areas, there are some notable differences between 6061 vs. 7075 aluminum.

During material selection, it is crucial to understand the various features of the materials in question. It is also essential to know the differences between the various CNC machinable aluminum alloys available. Therefore, this article aims to establish the features of 7075 aluminum vs. 6061 aluminum. This will show you where each of these alloys excels and where you should not use them.

6061 Aluminum Alloy in Review

This alloy is a renowned member of the 6000 series. It is often referred to as a jack of all trades due to its versatility and excellent mechanical properties. Its relatively low cost throws its usefulness up a significant notch.

6061 aluminum displays good machinability, excellent corrosion resistance, and good tensile strength. Manufacturers employ this for many extrusion projects because of its easy workability. It is a suitable option for applications in electrical products, automotive and aerospace products, piping, consumer products, and more.

7075 Aluminum Alloy in Review

A member of the 7000 series with zinc being its main component, 7075 aluminum is famous for its increased strength. Its increased mechanical strength accounts for its popularity in the defense and aerospace industries.

This alloy also withstands fatigue stress well, making it a reliable option in various industries. When you compare 7075 aluminum vs. 6061 aluminum, 7075 alloy has a comparatively higher cost. Its machinability is also at a reasonable level, but it is a little less weldable. The most common uses are in aircraft frames, plastic mold tooling, high-end bicycle components, etc.

6061 vs. 7075 Aluminum: The Differences

1. Alloy Series and Chemical Composition

You can deduce the first difference between 6061 and 7075 aluminum from their names. 6061 aluminum is a member of the 6000 class or alloy series. This class has silicon and magnesium as its primary alloy component. On the other hand, 7075 aluminum alloy is a member of the 7000 series. As a result, it uses zinc and copper as the primary alloying elements.

2. Mechanical Properties

Yield strength

7075 aluminum alloy has a higher yield strength than 6061 aluminum. Consequently, 7075 aluminum is able to withstand more pressure and more impact without deformation. The yield strength of 7075 aluminum is due to its chemical composition and heat treatment. However, the yield strength of 276MPa means that 6061 aluminum is not completely weak.

Thermal conductivity

Aluminum alloys are generally good conductors of heat. However, the thermal conductivity of 7075 aluminum vs. 6061 aluminum varies. This is also a result of their chemical compositions and heat treatment. 6061 aluminum’s thermal conductivity is slightly higher than that of 7075 aluminum. Therefore, it is an excellent choice in heat exchangers whose primary requirement is heat dissipation.

Electrical resistivity

Both 7075 and 6061 aluminum have low electrical resistivity, meaning that they are good electrical conductors. Thus, these alloys are suitable for electrical use. However, a difference between 6061 and 7075 aluminum is that 6061 has the lowest electrical resistivity. Therefore, it is a better conductor of electricity than 7075 aluminum.

Elasticity

Elasticity helps you to make sense of the resilience of materials and their resistance to deformation. It also correlates to material stiffness. Both 7075 and 6061 aluminum have similar responses to elastic deformation.

Temperature resistance

We analyze the temperature resistance of 7075 t6 vs. 6061 t6 by comparing their melting points. 7075 aluminum has a slightly lower melting point of 477 – 635°C than 6061 aluminum with a melting point of 582 – 652°C. Thus, 6061 alloy can withstand higher temperatures better than 7075 alloy. However, you should note that 7075 aluminum has an excellent reaction to heat treatment. It also allows for a much better distribution of elements in the metal.

Material hardness

The hardness of materials establishes their ability to resist deformation by indentation, penetration, or other means. Both alloys are hard enough to resist pressure and not crack or deform. However, 7075 aluminum is harder than 6061 aluminum.

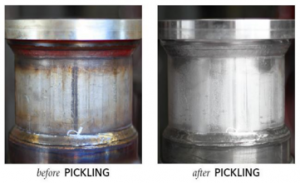

Corrosion resistance

6061 aluminum alloy is more resistant to corrosion than 7075. The reason for this is not far-fetched. There is a much higher amount of copper in the 7075 alloy than in 6061. Since copper reacts more with the environment, corrosion is bound to occur.

3. Fabrication Considerations

When dealing with fabrication, 6061 aluminum alloy has the edge over 7075 aluminum alloy. This is often due to the lower hardness and tensile strength of the 6061 alloy. Its lesser hardness allows for easy machining, while the lower tensile strength ensures better formability. You can join both materials by soldering, brazing, or use of adhesives. However, 6061 aluminum is weldable, while the 7075 variant is considered not weldable.

6061 vs. 7075 Aluminum: Applications

There is a kind of application ‘overlap’ between 6061 and 7075 alloys. Both alloys are useful for making automotive parts, aerospace components, and consumer products. However, they differ in the specific areas of use.

Some typical uses of 6061 aluminum alloy include:

- Building products

- Automotive parts

- Electrical products

- Bicycle frames

- Piping

Some typical uses of 7075 aluminum include, but are not limited to the following:

- Missile parts

- Aircraft components

- Gears and shafts

- Fuse parts

- Regulating valves

6061 vs. 7075 Aluminum: Which One to Choose?

Making a choice among alloys of the same metal may be a little tricky. As with several other things, your choice will depend on certain factors, the major one being the intended application. Other factors include manufacturing conditions and costs.

Being a versatile alloy, 6061 is suitable for several structural components. It is useful when:

- A lot of machining is required

- There is a need for a lot of welding on the part

- Corrosion is a concern

- Cost is a primary factor

On the other hand, 7075 aluminum is more useful when:

- High strength to weight ratio is crucial

- There will be high exposure of the plant to heat

- Lots of friction is involves

- Cost is less of a concern

Conclusion

We cannot overstate the importance of material choice in product development. Aluminum alloys are among the most widely used metal for fabrication processes. This article compared 7075 aluminum vs. 6061 aluminum based on various parameters, including their unique features and specific applications. Therefore, you must consider each material to ensure that you are selecting the ideal one for your project.